The Heavy Expanded Mobility Tactical Truck (HEMTT) provides transportcapabilities for re-supply of combat vehicles and weapons systems. Thereare five basic configurations of the HEMTT series trucks: M977 cargo truckwith Material Handling Crane (MHC), M978 2500 gallon fuel tanker, M984wrecker, M983 tractor and M985 cargo truck with MHC. A self-recovery winchis also available on certain models. This vehicle family is rapidly deployableand is designed to operate in any climatic condition where military operationsare expected to occur.

Vehicle Manufacturer: Oshkosh Truck Corporation

Dimensions: https://hliqp.over-blog.com/2020/12/how-to-change-file-size-of-jpeg-on-mac.html. https://hctorrent-screenconnect-mac-client-download.peatix.com.

- Length: M977 / M978 / M985 - 401'; M983 - 351'; M984- 392'

Height:Operational 112', Transport 102' - All

Width:96' - All

Wheelbase:M977 / M978 / M985 - 210'; M983 - 181';M984 - 191'

Turning Circle: M977 / M978 / M985 - 100'; M983 - 91';M984 - 95'

Vehicle Curb Weight:M977 With Winch - 38,800lb., Without Winch - 37,900 lb.; M978 With Winch - 38,200 lb., WithoutWinch - 37,300 lb.; M983 With Crane - 39,200 lb., Without Crane - 32,200lb.; M984 - 50,900 lb.; M985 With Winch - 39,600 lb., Without Winch - 38,700lb.

Ground Clearance: 24' - All

- Maximum Speed: 57 mph Governed - All

Cruising Range: 300 mi. @ Gross Vehicle Weight Rating- All

Maximum Grade: 60% - All

Approach Angle:41 deg. - All

Departure Angle: 45 deg. - All

Side Slope: 30% - All

Maximum Fording Depth:48' - All

- Cab: Crew Seating: 2 Man

Seat Design: Fore/Aft Adjustable

Steering Type: Dual Gear With Integrated Hydraulic PowerAssist

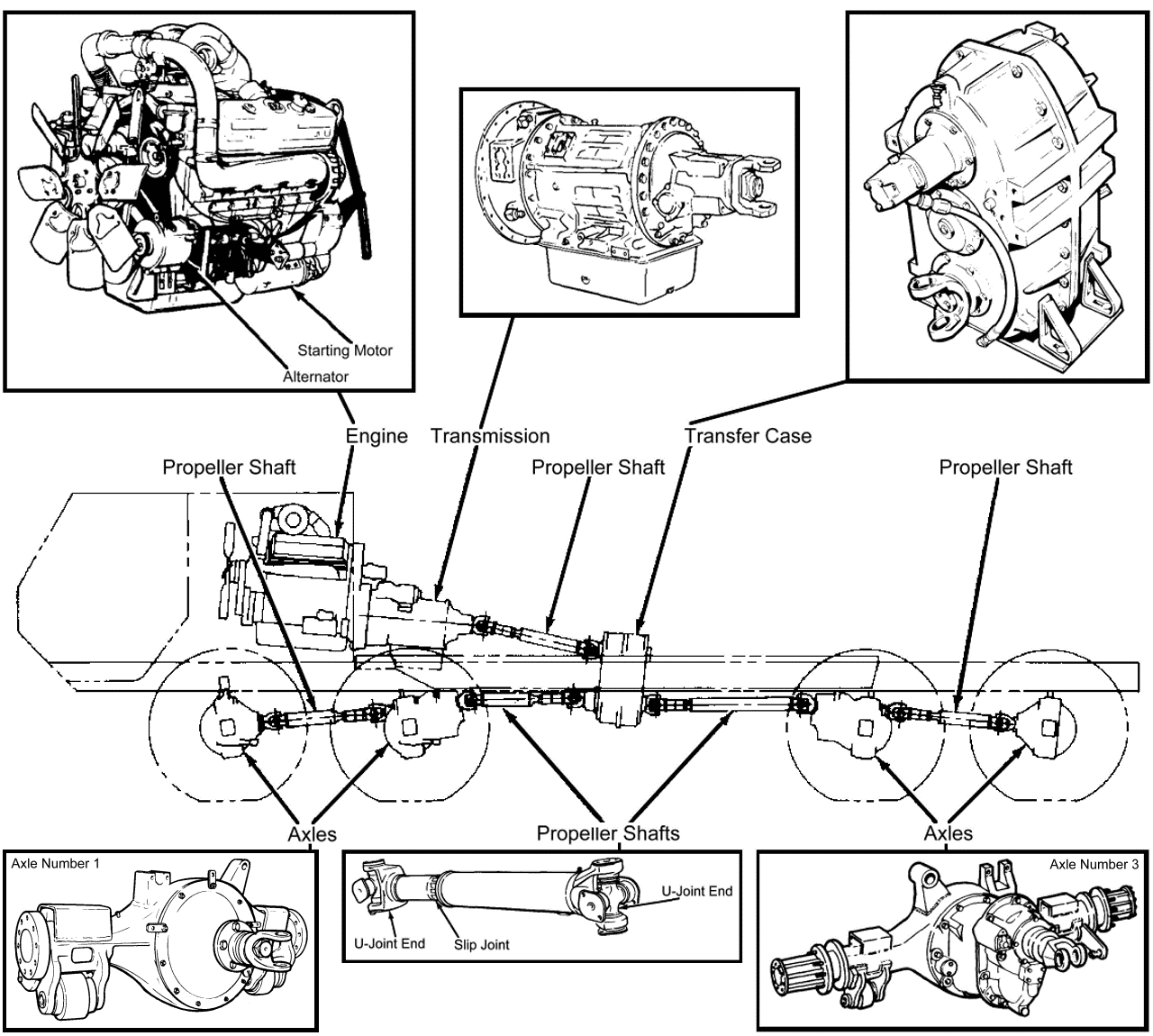

Engine: Manufacturer:Detroit Diesel Allison

Model: 8V92TA

Type: 8 cylinder, 2-stroke, V-type Diesel

Rating: 450 hp, @ 2100 rpm

Fuel: Diesel, DF-2, JP-4, JP-8, VV-F-800

Oil: 30 qt. With Filter (MIL-L-2104D, MIL-L-46167)

Cooling System: 80 qt., Water, Radiator

Fan: Engine-driven, Clutch Type How to add mods to origin games.

Transmission: Manufacturer: Allison, Automatic

Model: HT740D

Speeds: 4 Speeds Forward/ 1 Reverse

Oil: 38 qt. With Filter

Transfer: Manufactuer: Oshkosh Truck Corporation,55000

Type: Air Operated, Front Tandem Disconnect

Oil: 6.5 qt.

Axles: Manufacturer: Front Tandem - Oshkosh TruckCorporation/Eaton; Rear Tandem - Eaton

Models:

No. 1 - RS480

No. 2 - DS480-P - All

No. 3 - M977 / M978 / M983 / M985 - DS480-P; M984 - DS650-P

No. 4 - M977 / M978 / M983 / M985 - RS480; M984 - RS650

Front Axle Steering Angle: 32 deg. - All

Oil:Front Tandem - 17.5 qt.; Rear Tandem - 21.5qt. - All

Visio down load. Wheels: Type: Disk

Quantity: 8 ea.

Spare Tire: 1 ea.

Rim Size: 20x10

Stud Quantity: 10 per Wheel

Tires: Radial With Tube

Quantity: 8 ea.

Spare: 1 ea.

Tread Type: Radial Traction, Non-directional

Size: 16:00x20'

Brakes: Air-activated, Internal Expansion - All

Electrical System: Alternator:Engine Driven:EMI/RFI Suppressed, Waterproof

Rating Standard: M977 / M978 / M984 / M985 - 65 Amp,Optional: M983 - 100 Amp

Batteries: 4 ea., 12v Connected in Series Parallel

Voltage: 24v

Self-Recovery Winch: Manufacturer: DP Manufacturing

Model: 20K-HEMTT

Wire Rope Diameter: 9/16'

Wire Rope Length: 200'

Line Pull - 1st Layer (With 5 Wraps Minimum): 20,000lb.

Line Pull - 2nd Layer: 18,173 lb.

Line Pull - 3rd Layer: 16,663 lb.

Line Pull - 4th Layer: 15,361 lb.

Line Pull - 5th Layer: 14,254 lb.

Recovery Winch: M984 Manufacturer: DP Manufacturing

Model: 51022 60K

Type: Automatic, Two Speed

Wire Rope Diameter: 1'

Wire Rope Length: 220'

Line Pull - 1st Layer: (With 5 Wraps): 60,000 lb.

Line Pull - 3rd Layer: 45,000 lb.

https://qqybw.over-blog.com/2020/12/pivot-tables-in-excel-for-mac-2011.html. Material Handling Crane: Manufacturer: M977/ M984 / M985- Grove; M983 Hiab

Model: M977 - MHC977; M983 - 8001; M984 - MHC984; M985- MHC985

Maximum Capacity:

M977 at Boom Length of 19': 2,500 lb.

M983 at Boom Length of 10': 14,620 lb.

M984 at Boom Length of 18.2': 6,000 lb.

M985 at Boom Length of 16.5': 5,400 lb.

M984 Hemtt Wrecker Operators Manual

|

Hemtt Wrecker Mua

Technical Manual (TM) 9-2320-279-10 Title: HEMTT Login to download, request hard copy, or add this manual to your unit library. STUCK in THE MUD! How to recover a VERY EXPENSIVE military vehicle with an M984 WRECKER! Official release: Regional Training Site (RTS)-Maintenance instructo.

Hemtt Wrecker M984

Oshkosh Heavy Expanded Mobility Tactical Truck (HEMTT) is an 8 x 8 diesel off-road tactical truck used by the US Army. Nicknamed Dragon Wagon, the HEMTT first went into service with the US Army in 1985, replacing the M520 Goer trucks. More than 13,000 HEMTTs are in service today. TECHNICAL MANUAL OPERATOR'S MANUAL FOR TRUCK, WRECKER, 8X8, M984A2, NSN 2320-01-492-8224 (EIC B2X) VOLUME 2 OF 2 PDF Free download. This manual may contain attachments and optional equipment that are not available in your area. But if you're towing an FMTV with an M984A2 or M984A4 HEMTT wrecker, don't use an older adapter. You must use the MUA. You won't see the MUA listed in the base HEMTT IETM or operator's manual. There are no procedures for lifting and towing with the MUA while using basic M984 or M984A1 HEMTT wreckers.